-

+86-371-86159555

The Designing for 50T/D Corn / Maize Grinding Mill:

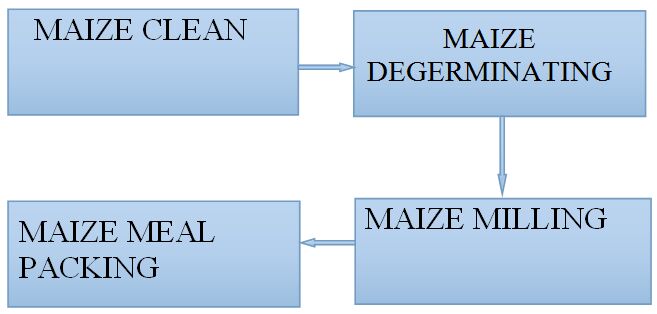

1. We supply you complete line machine from cleaning, to degerminting, milling, packing, controlling system to produce super white maize meal.

2. Supply you pipes, platform, cables from control penal to each machine, and one year spare parts, what you need supply is workshop, electric, water and 1 miller, 4-6 workers.

3. The pips in milling system will be stainless steel, more durable and longer lasting.

4. The control system we use PLC touch screen, the technical flow will show on the screen, and achieve one button boot device, more intelligent.

5. Moisture damper Stainless Steel, Bin- direction screw, prevent free water, make sure the maize degerminating easy.

6. Degerminator with Japan and South Africa Technology to scrub the maize germ, with the minimum reduce in size of the broken fragments ensure produce super white, purity high quality maize flour with low fat.

7. Before packaging design with Micro doser to mixed vitamins in maize meal ( to strengthen the national constitution)

8. We will also suppler engineer to install the machine for you and training your workers how to operate machines, and teach workers how to maintain the machine.

Explain for designing

A. Capacity: Processes 50 tons of Maize one day(24 hours).

B. The quality of the raw grain: Africa Maize(soft or hard)

C. Working system: 24 hours one day.

D. The quality index of the corn (Remark: according to the customer’s standard to adjust designing ):

E. End products index:

1.Corn flour fineness:40-200 meshes (the flour fineness can be adjusted)

2.Sand content:<0.02%

3.Magnetic metal content:< 0.003

4.Moisture storage:13.5-14.5%

5.Fat content:0.5—1%

6.Appearance and taste: bright color, fine powder, high quality and pure taste.

Technological designing and product index:

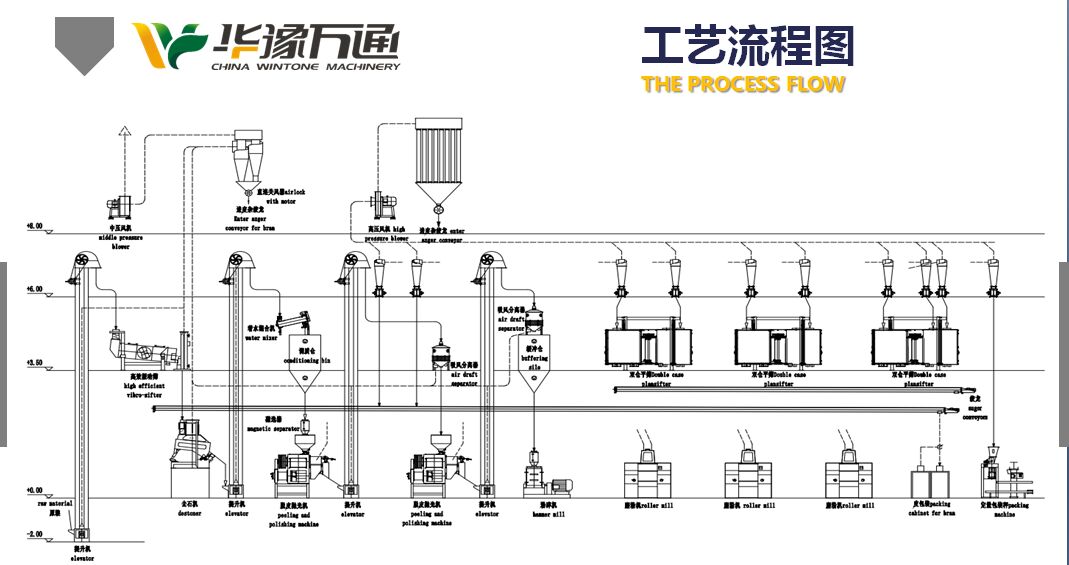

The Principe of the technological designing: to choose the equipment should be guarantee the demand of the craft function and various product quality, it is consisted by most advanced cleaning machine of China.The technological design is reasonable and adjusts vivid, strong adaptability,advance equipment, high automation degree, credibility function, economy and practicality, good cleaning part. Choose the most popular dry cleaning methods to process the maize to produce non-pollution maize meal and maize flour. The stability of the machines is strong, the function is credibility, economy and practicality, the quality of the maize meal and maize flour is stable, index is forerunner.

1) Maize cleaning

Maize cleaning: cleaning process uses vibrating sieve, destoner, magnetic separators for drying cleaning. We adopt world-class degerminator to get whole pcs germ,and use gravity table to getting the maize germ.

We use double screw damper for keeping moisture the maize. microcomputer control the water damper. add water to ensure a more accurate and uniform water,prevent free water; the use of degerminator for peeling maize into small pieces and embryo separated in order to ensure quality and by fully mechanized and use.

2) Milling technology

Milling process uses light maize milling subdivision research methods, advanced maize milling and sifting equipment to ensure its process efficiency, using a set of pneumatic conveying systems, five blower air system, the process can also produce 2-4 kinds of high-quality final products. the fat content- not more than 1%.

Staff assignments

According to the conventional business daily processing 30 tons of maize flour mill, the general annual 350days at full capacity, three shifts of production, need every single day every shift one miller 3 workers.

|

Item |

Spec. and Characteristic |

Hard maize |

Soft maize |

|

|

Moisture content(%) |

≤14.5 |

≤14.0 |

|

Hard maize(minimum)(%) |

60 |

45 |

|

Quality |

Density(kg/l) |

≥660 |

≥660 |

|

Weight of thousand maize (g) |

295(minimum) |

280(minimum |

|

|

Ash (%) |

1.75(maximum) |

1.7(maximum) |

|

|

Impurity |

Inorganic impurities(%) |

0.4(maximum) |

0.5(maximum) |

|

Other grains (%) |

0.3(maximum) |

0.5(maximum) |

|

|

Incomplete rate(%) |

4.0(maximum) |

6.0(maximum) |

Live pictures:

Our 50Ton Maize Milling Project:

VIDEO:

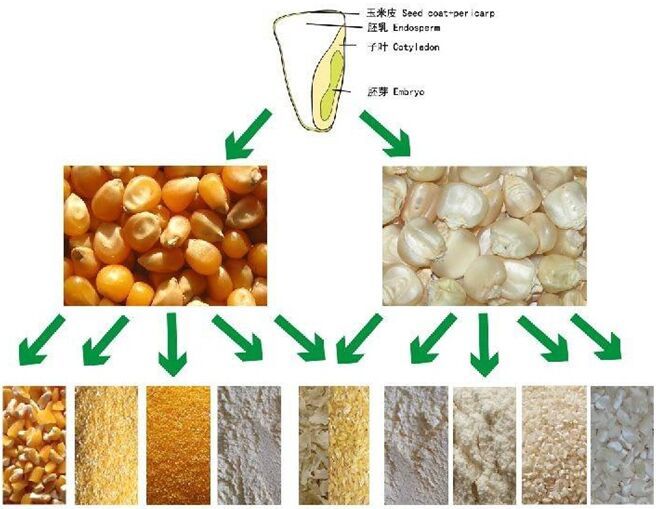

End products:

Yellow maize processing:

White maize processing:

Overseas Offices:

1.Office in Kenya:

Address: Mudher Industrial Park, Off Mombasa Road, Next to Soham Petrol Station, Nairobi, Kenya

Contact: Emma

Email: info@wintonemachinery.com

2.Office in Uganda:

Address: Plot 27. Luthuli Avenue, Buglobi P.O.Box 8338. Kampala, Uganda

Contact: Sophia

Email: wintone16@wintonemachinery.com

3.Office in Ethiopia:

Address: No.4 Floor, Yobex Building, Mexico Area, Addis Ababa, Ethiopia

Contact: Jaspher

Email: wintone16@wintonemachinery.com

+86-371-86159555

86635803

No. 57 Science Avenue

Zhengzhou, Henan, China

7*24 hours

Human services